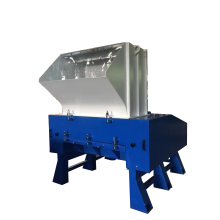

Plastic Jerry Can/ Bottle/ Container Blowing Machine

Basic Info

Model No.: TJ-HB20L

Product Description

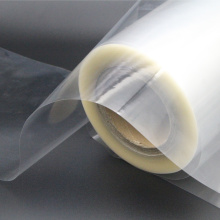

Mainly used for producing middle and small blow products of transparent

Line (composite) lubricating oil bucket, pesticide bottle, cosmetic bottle and so on. The inner and outside composite can reduce the production cost, and the transparent line can show the capacity.

Material: PE, PP, PVC, PA

Dia. Of main screw: 45, 55, 65 mm

L/D ratio of main screw: 25 L/D

Die quantity: 1, 2

Clamping force: 25, 40, 40 KN

Total power: 26-48 KW

Product Description What is the details of our Series of Blow Molding Machine: Two layers of 15~230L plastic bottle/drum? 1. The inner and outside composite can reduce the production cost, and the transparent line can show the capacity. 2. The servo valve and controller are from MOOG(USA), and both devices are able to ensure the evenness of wall thickness and the products' elegant appearance. 3. The low-voltage electrical apparatus comes from Siemens (Germany), and Schneider (France). 4. It can be installed with programmable computer control and realize whole line intelligentize. What is the Specification of our Series of Blow Molding Machine:Two layers of 15~230L plastic bottle/drum ?

Specification |

| TJ-ZKT45 | TJ-ZKTF45 | TJ-ZKT65 | TJ-ZKTF65 |

Material |

| PE, PP, PVC, PA... | |||

Max. capacity of product | L | 2 | 9 | ||

Die quantity | set | 1.2 | |||

Dimensions(L*W*H) | m | 2.2*1.32*2.15 | 2.9*2.1*2.85 | ||

Total weight(approx) | T | 3.1 | 3.2 | 5.6 | 5.8 |

Extrusion system | |||||

Dia. of main screw | mm | 45 | 65 | ||

L/D ratio of main screw | L/D | 25 | 25 | ||

Dia. of auxiliary screw | mm | / | 30 | / | 45 |

L/D ratio of auxiliary screw | L/D | / | 25 | / | 25 |

Dia. of screw for lisuid level line | mm | 20 | 20 | ||

L/D ratio of screw for liquid level line | L/D | 20 | 20 | ||

Clamping system | |||||

Clamping force | KN | 25 | 40 | ||

Distance between platens | mm | 100-320 | 100-550 | ||

Max. size of mould(W*H) | mm | 220*270 | 350*400 | ||

Power | |||||

Driving power of main ectruder | KW | 5.5 | 15 | ||

Driving power of auxiliary extruder | KW | / | 2.2 | / | 5.5 |

Driving power motor for liquid level line | KW | 0.75 | 0.75 | ||

Motor power of oil pump | KW | 5.5 | 5.5 | ||

Total power(approx) | KW | 26 | 28 | 43 | 48 |

Water pressure | Mpa | 0.2-0.3 | 0.2-0.3 | ||

Water consumption | L/min | 25 | 50 | ||

Air pressure | Mpa | 0.7 | 0.7 | ||

Air consumption | m3/min | 0.4 | 0.4 | ||

Average energy consumption(approx) | KW | 13 | 15 | 22 | 25 |

Product Description What is the details of our Series of Blow Molding Machine: Two layers of 15~230L plastic bottle/drum? 1. The inner and outside composite can reduce the production cost, and the transparent line can show the capacity. 2. The servo valve and controller are from MOOG(USA), and both devices are able to ensure the evenness of wall thickness and the products' elegant appearance. 3. The low-voltage electrical apparatus comes from Siemens (Germany), and Schneider (France). 4. It can be installed with programmable computer control and realize whole line intelligentize. What is the Specification of our Series of Blow Molding Machine:Two layers of 15~230L plastic bottle/drum ?

Product Description What is the details of our Series of Blow Molding Machine: Two layers of 15~230L plastic bottle/drum? 1. The inner and outside composite can reduce the production cost, and the transparent line can show the capacity. 2. The servo valve and controller are from MOOG(USA), and both devices are able to ensure the evenness of wall thickness and the products' elegant appearance. 3. The low-voltage electrical apparatus comes from Siemens (Germany), and Schneider (France). 4. It can be installed with programmable computer control and realize whole line intelligentize. What is the Specification of our Series of Blow Molding Machine:Two layers of 15~230L plastic bottle/drum ? Specification |

| TJ-ZKT45 | TJ-ZKTF45 | TJ-ZKT65 | TJ-ZKTF65 |

Material |

| PE, PP, PVC, PA... | |||

Max. capacity of product | L | 2 | 9 | ||

Die quantity | set | 1.2 | |||

Dimensions(L*W*H) | m | 2.2*1.32*2.15 | 2.9*2.1*2.85 | ||

Total weight(approx) | T | 3.1 | 3.2 | 5.6 | 5.8 |

Extrusion system | |||||

Dia. of main screw | mm | 45 | 65 | ||

L/D ratio of main screw | L/D | 25 | 25 | ||

Dia. of auxiliary screw | mm | / | 30 | / | 45 |

L/D ratio of auxiliary screw | L/D | / | 25 | / | 25 |

Dia. of screw for lisuid level line | mm | 20 | 20 | ||

L/D ratio of screw for liquid level line | L/D | 20 | 20 | ||

Clamping system | |||||

Clamping force | KN | 25 | 40 | ||

Distance between platens | mm | 100-320 | 100-550 | ||

Max. size of mould(W*H) | mm | 220*270 | 350*400 | ||

Power | |||||

Driving power of main ectruder | KW | 5.5 | 15 | ||

Driving power of auxiliary extruder | KW | / | 2.2 | / | 5.5 |

Driving power motor for liquid level line | KW | 0.75 | 0.75 | ||

Motor power of oil pump | KW | 5.5 | 5.5 | ||

Total power(approx) | KW | 26 | 28 | 43 | 48 |

Water pressure | Mpa | 0.2-0.3 | 0.2-0.3 | ||

Water consumption | L/min | 25 | 50 | ||

Air pressure | Mpa | 0.7 | 0.7 | ||

Air consumption | m3/min | 0.4 | 0.4 | ||

Average energy consumption(approx) | KW | 13 | 15 | 22 | 25 |

Product Categories : Plastic Blow Molding Machine

Premium Related Products