Plastic Extrusion Mould/Die Head for Cabinet and Furniture Board

Basic Info

Model No.: ST-2

Product Description

Model NO.: ST-2 Surface Finish Process: Polishing Plastic Material: PVC Application: Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware Design Software: AutoCAD Certification: CE, SGS Customized: Customized SCR17 Material: Single or Multi-Cavity High Polished Surface: Pre-Testing Before Delivery Specification: CE HS Code: 84772090 Shaping Mode: Extrusion Mould Mould Cavity: Multi Cavity Process Combination Type: Compound Die Runner: Hot Runner Installation: Fixed Standard: HASCO Special Design: Long Product Life Variuos Size and Shapes: PVC Foam Board Mould Trademark: Sana-tory Origin: China Plastic Extrusion Mould/Die Head for Cabinet and Furniture Board

1, Choose reasonable length for calibration mold according to different thickness, to make evenness of final products surface within 3/10000.

2, Larger cooling water flow, speeder flowing speed and even cooling water hole arrangement go make the products cooling and calibration fast, even and the products size more exact.

3, Adjustable underneath lifting cylinder, accurate position sliding rail, with good outlooking and easy operation.

4, Wide angle butterfly type sunner way design, to make sure the pressure of the mould more even, and flow more accurate.

5, According to different wall thickness of the products, to choose different reduction ratio and the size of stable zones, to ensure the products production more stable, production period longer, foaming multiplying power larger.

6, Inner wall choosr independent material feeding design, to make foaming products surface color and density uniformity.

7, Short period for mould testing, within 3 days can finish testing if all the working conditions are mature.

Production description:

Contact us if you need more details on Extrusion Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Extrusion Die Head、Board Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

1, Choose reasonable length for calibration mold according to different thickness, to make evenness of final products surface within 3/10000.

2, Larger cooling water flow, speeder flowing speed and even cooling water hole arrangement go make the products cooling and calibration fast, even and the products size more exact.

3, Adjustable underneath lifting cylinder, accurate position sliding rail, with good outlooking and easy operation.

4, Wide angle butterfly type sunner way design, to make sure the pressure of the mould more even, and flow more accurate.

5, According to different wall thickness of the products, to choose different reduction ratio and the size of stable zones, to ensure the products production more stable, production period longer, foaming multiplying power larger.

6, Inner wall choosr independent material feeding design, to make foaming products surface color and density uniformity.

7, Short period for mould testing, within 3 days can finish testing if all the working conditions are mature.

Production description:

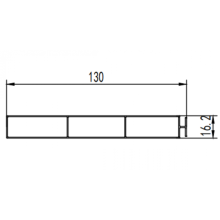

| Name | PVC extrusion method foam plate foam board mould |

| Size | Various sizes and shapes |

| Mould | 3Cr17, 3Cr17MoNiV or as per your request |

| Mould cavity | Single or multi-cavities |

| Mould composition | Die head, heating bands, calibrators and water tank |

| Feature | High polished surface, top and bottom cover co-extrusion |

| Test | All extrusion tooling will be tested to get the satisfied sample before delivery |

| Sample | Sample profile will be arranged by express / courier for customer approval |

| Service | Pre-testing in our factory and the test in the customers' sites. If you need, we can send the technicians to your site to test the tool. We guarantee the one-year production. |

| Delivery | 50 days more or less |

| Package | Anti-shock strong wooden case package or according to the customer's requirement |

Contact us if you need more details on Extrusion Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Extrusion Die Head、Board Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Extrusion Mould/Die

Premium Related Products

Other Products

Hot Products

EPE Foamed Net/Foamed Package Mesh MachinePE Heat Shrink Film MachineWood Plastic Profile Production Line (JG-MSX)Plastic Net Marking MachineWPC Three Layers Skinning Foam Plates Making Machine (JG-MSC)pvc hot-cutting pelletizing lineHot sale PET sheet production line PET sheet extruder plastic pet sheet making machine made in ChinaEuropean tech, chinese price high efficient parallel twin screw extruderPVC pipe machine with good price / PVC pipe production line/ PVC pipe making machineHigh quality HDPE steel reinforce pe pipe production lineplastic recycling machineryhorizontal mixing machine for plastic industryNew generation WPC extrusion line,WPC production line,WPC machineryFT single wall corrugated pipe extrusion line pvc pipe extruding linePlastic pipe belling/expanding machine for pipe production linehot sale high quality double pvc pipe making machine