CO2 XPS Foamed Heat Insulation Board Extruder Line

Basic Info

Model No.: JG-XPS75P200

Product Description

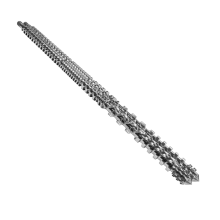

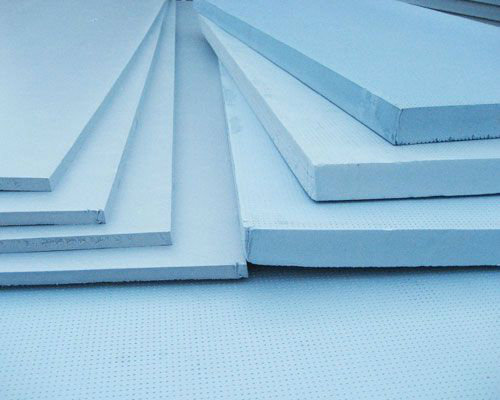

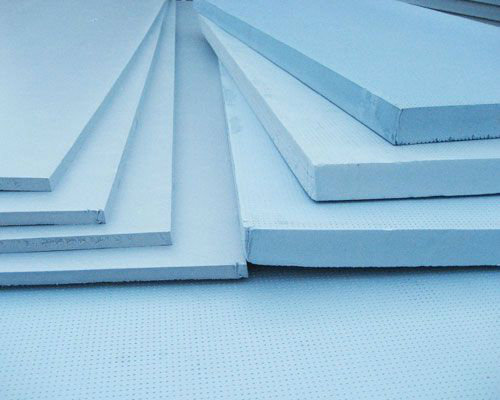

Model NO.: JG-XPS75P200 Plastic Processed: XPS Feeding Mode: One Feed Screw: Twin-Screw Screw Channel Structure: Deep Screw Automation: Automatic Trademark: tongjia Origin: China Type: Sheet Extruder Product Type: Granulating Extruder Assembly Structure: Integral Type Extruder Engagement System: Full Intermeshing Exhaust: Exhaust Computerized: Computerized Specification: ISO, CE HS Code: 84772090 XPS foamed sheet, also named as Polystyrene Extrusion Plastic Sheet (XPS for short) has a perfect closed-pore alveolate structure. Its density, water absorption, coefficient of heat conducting and the coefficient of steam pervasion are all lower than those of other sheet heat insulating materials and they have the characteristics of strong intensity, light material, airtight, anticorrosion, ageing resistance, low cost, etc. It has been widely used in the fields of heat preservation in the construction industry and the highway, railway, airport, square of the heat preservation and household fitment. It is the generally acknowledged and the best heat insulator in the market at present.

The Application Specification of The Product:

It is used in steel construction workshop, iron sheet house and colored ripple tile for heat preservation;

It is used for making up the heat insulation board in the refrigeration storehouse for cold preservation and waterproofing;

It is used for laying the bedding under the road bed of the highway for buffering and controlling the frost heaving of the ground;

It is used for waterproofing and heat preservation of residential building, office building, the factory wall and roof;

It is used for laying the bedding under the floor for the functions of heat insulation, dampproof and sound insulation;

It is used in the ventilation piping of central air conditioner for heat insulation and heat preservation.

Our Services 1.12 Hours----Your reply will be replied within 12 hours. 2.Service----We offer your professional service in fluent English. 3.Delivery----1~3 months. 4.Free Design----Professional designers, free designs. 5.Certificates----Third-party verification service provider 6.Service----OEM service offered; Design service offered; Buyer label offered. Company Information Why choose us? 1.Our factory was founded in 1953 and we are market-leader in this line in china. 2.In the plastic machinery field, we have more than 20 years of relevant experience. 3.Our products extend all over the national and over 60 countries and areas of the world. 4.Our spare parts are brand components. 5.Engineering team provide you with the most suitable model towards your products. 6.Technical training and service is the advantage of us. 7.Tongjia Machinery hopes to create nice future with clients from home to overseas. 8.Welcome overseas people to our factory site visits.

Contact us if you need more details on XPS Foaming Board Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PS Foamed Machinery、XPS Foamed Board Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

The Application Specification of The Product:

It is used in steel construction workshop, iron sheet house and colored ripple tile for heat preservation;

It is used for making up the heat insulation board in the refrigeration storehouse for cold preservation and waterproofing;

It is used for laying the bedding under the road bed of the highway for buffering and controlling the frost heaving of the ground;

It is used for waterproofing and heat preservation of residential building, office building, the factory wall and roof;

It is used for laying the bedding under the floor for the functions of heat insulation, dampproof and sound insulation;

It is used in the ventilation piping of central air conditioner for heat insulation and heat preservation.

| Model | JGXPS135/150 | JG-XPS170/200 | JG-XPS80/156Z | ||||

| Extruder | Φ 135/32 | Φ 150/34 | Φ 170/28 | Φ 200/30 | Φ 80/156 bipyramid | Φ 150/34 | |

| Heating power | KW | 50 | 52 | 78 | 100 | 33 | 52 |

| Driving power | KW | 75 | 55 | 90 | 90 | 55 | 55 |

| Board thickness | mm | 20, 25, 30, 40, 50, 60, 75, 100 | 40, 50, 60, 75, 100, 120 | 20, 25, 30, 40, 50, 60, 75, 100 | |||

| Width of board | mm | 600, 900, 1200 | 600, 900, 1200 | 600, 900, 1200 | |||

| Length of board | mm | 1200, 1250, 2450, 2500 | |||||

| Output (approx) | kg/h | 320 | 380-500 | 320-400 | |||

| Installed capacity (approx) | KW | 260 | 400 | 250 | |||

| Dimension (L × W × H) (appr. ) | m | 40× 10× 4 | 50× 12× 4 | 40× 9× 4 | |||

| Total weight (appr. ) | T | 28 | 33 | 29 | |||

Our Services 1.12 Hours----Your reply will be replied within 12 hours. 2.Service----We offer your professional service in fluent English. 3.Delivery----1~3 months. 4.Free Design----Professional designers, free designs. 5.Certificates----Third-party verification service provider 6.Service----OEM service offered; Design service offered; Buyer label offered. Company Information Why choose us? 1.Our factory was founded in 1953 and we are market-leader in this line in china. 2.In the plastic machinery field, we have more than 20 years of relevant experience. 3.Our products extend all over the national and over 60 countries and areas of the world. 4.Our spare parts are brand components. 5.Engineering team provide you with the most suitable model towards your products. 6.Technical training and service is the advantage of us. 7.Tongjia Machinery hopes to create nice future with clients from home to overseas. 8.Welcome overseas people to our factory site visits.

Contact us if you need more details on XPS Foaming Board Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about PS Foamed Machinery、XPS Foamed Board Production Line. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Foaming Machinery

Premium Related Products

Other Products

Hot Products

EPE Foamed Net/Foamed Package Mesh MachinePE Heat Shrink Film MachineWood Plastic Profile Production Line (JG-MSX)Plastic Net Marking MachineWPC Three Layers Skinning Foam Plates Making Machine (JG-MSC)pvc hot-cutting pelletizing lineHot sale PET sheet production line PET sheet extruder plastic pet sheet making machine made in ChinaEuropean tech, chinese price high efficient parallel twin screw extruderPVC pipe machine with good price / PVC pipe production line/ PVC pipe making machineHigh quality HDPE steel reinforce pe pipe production lineplastic recycling machineryhorizontal mixing machine for plastic industryNew generation WPC extrusion line,WPC production line,WPC machineryFT single wall corrugated pipe extrusion line pvc pipe extruding linePlastic pipe belling/expanding machine for pipe production linehot sale high quality double pvc pipe making machine