PVC Door Board Production Line/WPC Door Board Making Machine

Basic Info

Model No.: ST-92

Product Description

Model NO.: ST-92 Condition: New Customized: Customized Power Source: Electric Product Type: Plastic Sheet Screw: Twin-Screw Computerized: Computerized Trademark: Sana-tory Origin: China Certification: SGS, CE Screw Design: Double-Screw Application: Laser Engraving, Food, Sheet, Plates, Machinery & Hardware, Beverage Automatic Grade: Automatic Allor Steel: Sheet Extruder Automation: Automatic Plastic Processed: CAD Design Specification: CE HS Code: 84772090 PVC Door Board Production Line/WPC Door Board Making Machine

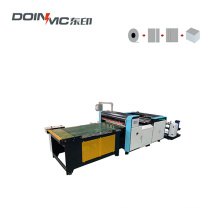

PVC WPC Door Board Production Line is designed according to international latest technology, mixed PVC, PP, PE with plant fiber symmetrically. It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form.

1. Using international advanced CAD design software, 38CrMoAIA alloy steel with superior quality and coating metal on surface, special mixing material function and high plastify capacity of screw and barrel.

2. Cooling system of screw core use constant temperature system controlled by hot oil, so that material can be plastified well; And barrel uses vacuum exhaust type, so that moisture content can volatilize fully and keep product quality.

3. Low voltage apparatus uses import brand with advantages of precise control and convenient operation. It also can be installed with programmable computer control and realize whole line intelligentize.

Main technical parameters:

Contact us if you need more details on PVC Board Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about WPC Board Production Line、Board Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

PVC WPC Door Board Production Line is designed according to international latest technology, mixed PVC, PP, PE with plant fiber symmetrically. It adopts high-efficiency conical double-screw extruder with forcible cooling system to extrude and form.

1. Using international advanced CAD design software, 38CrMoAIA alloy steel with superior quality and coating metal on surface, special mixing material function and high plastify capacity of screw and barrel.

2. Cooling system of screw core use constant temperature system controlled by hot oil, so that material can be plastified well; And barrel uses vacuum exhaust type, so that moisture content can volatilize fully and keep product quality.

3. Low voltage apparatus uses import brand with advantages of precise control and convenient operation. It also can be installed with programmable computer control and realize whole line intelligentize.

Main technical parameters:

| Model for extruder | | SJSZ80/156 | SJSZ92/188 |

| Screw dia. | mm | 80/156 | 92/188 |

| Screw quantity | (Piece) | 2 | 2 |

| Rotational speed | r/min | 1-38 | 1-32.9 |

| Main extruder power | KW | 75 | 132 |

| Heating power (approx) | KW | 36 | 45 |

| Extrudsion output | kg/h | 250-400 | 400-500 |

| Model for assistant machine | | ST600 | ST900 |

| Max. product size | mm | 600 | 900 |

| Draw-off height | mm | 150 | 150 |

| Draw-off force | KN | 30 | 40 |

| Draw-off speed | m/s | 0-3 | 0-2.5 |

| Auxiliary machine’ s total power | KW | 30 | 40 |

| Cooling water consume | m 3 /h | 9 | 12 |

| Compressed air pressure | Mpa | 0.6 | 0.6 |

Product Categories : Plastic Sheet/ Board Machine

Premium Related Products

Other Products

Hot Products

EPE Foamed Net/Foamed Package Mesh MachinePE Heat Shrink Film MachineWood Plastic Profile Production Line (JG-MSX)Plastic Net Marking MachineWPC Three Layers Skinning Foam Plates Making Machine (JG-MSC)pvc hot-cutting pelletizing lineHot sale PET sheet production line PET sheet extruder plastic pet sheet making machine made in ChinaEuropean tech, chinese price high efficient parallel twin screw extruderPVC pipe machine with good price / PVC pipe production line/ PVC pipe making machineHigh quality HDPE steel reinforce pe pipe production lineplastic recycling machineryhorizontal mixing machine for plastic industryNew generation WPC extrusion line,WPC production line,WPC machineryFT single wall corrugated pipe extrusion line pvc pipe extruding linePlastic pipe belling/expanding machine for pipe production linehot sale high quality double pvc pipe making machine