Used Motor Oil Refinery Machine

Basic Info

Model No.: LL-10

Product Description

We,Shangqiu Zhongming Eco-Friendly Equipment Co., Ltd , Dominated in Recycling various solid waste to be oil or diesel since 2008. Our production as below: Crude Oil Distillation Machine, Waste Engine Oil Distillation Machine,Tyre Oil Distillation Machine, Plastic Oil Distillation Machine,Tyre Pyrolysis Machine,Plastic Pyrolysis Machine,etc... We have exported our machines to more than 50 countries, help customer making huge profit and got good evaluations from worldwide customer. Welcome your visit and looking forward to our earlier cooperation.

1. The name of machine

Used Motor Oil Refinery Machine

2. The Production technology

(1) Adopt the new technology of high vacuum, atmospheric pressure reduction, catalytic pyrolysis and distillation.

(2) Special catalyst , filter composite material.

(3) Continuous working.

3. The brief introduction of the machine

The machine is distillate diesel and gasoline by using used engine oil . the main configuration device; pretreatment reactor, horizontal rotary heating furnace, atmospheric fractionating tower, condenser, cooling water tank, oil-water separator, filter , refining filter system; heating system; distillation system;cooling system, vacuum and exhaust gas recycling system; smoke and dust removal system; fire safety, explosion-proof, electrostatic grounding system; recycling water treatment system; control system. The machine is heated by horizontal rotary heating furnace and can be continuously manufactured with capacity from 5ton/day to 100ton/day(according to customer demand, production line can be customized).

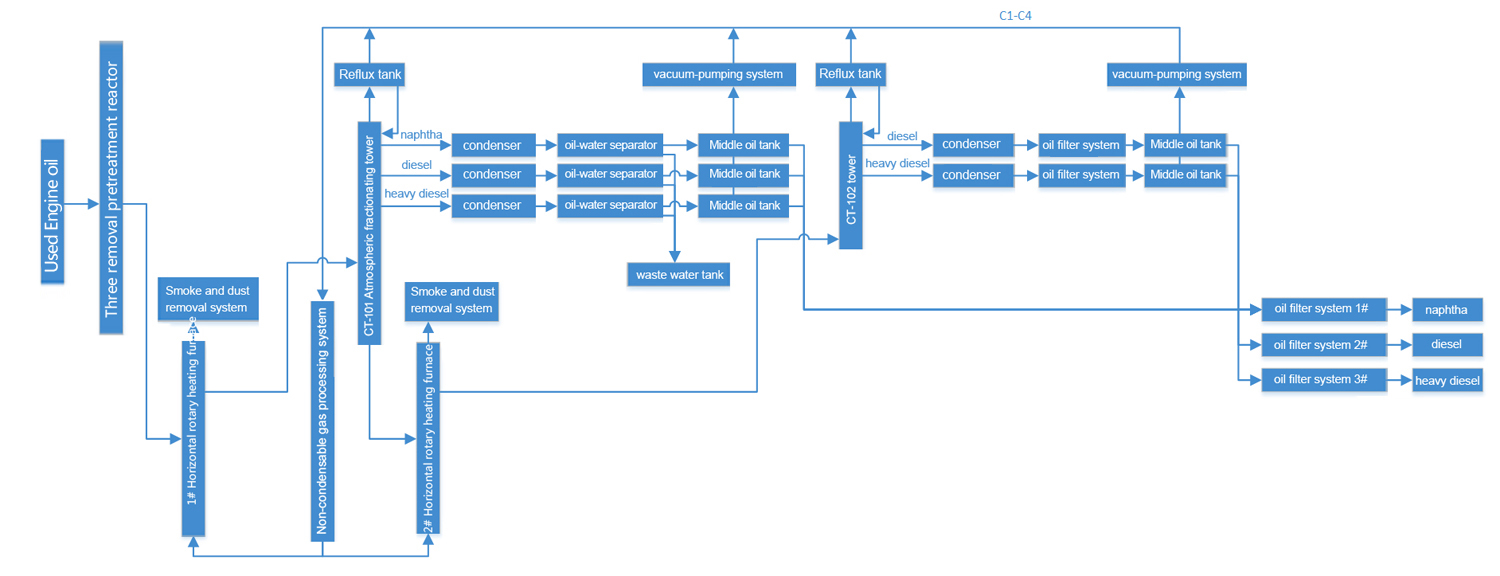

4. The flow chart and 3D drawing

5. Brief introduction of technological process

Pump used engine oil into the pretreatment tank through oil pump, then adding flocculant and other additives for removing water, impurity and colloid. Open air compressor, Injected compressed air into pretreatment reactor tank for mixing oil. stirring intensity by the compressed air control valve control, At same time open pretreatment heating circulating oil pump, the used engine oil in the reactor tank is delivered to the waste heat energy processor for heating by exchange heating. the used engine oil circulation heating gradually to 40-80℃, with heating with stirring, stirring time is 40-60 mins, after static precipitation 3-4 hours, then remove water and slag.

The used engine oil will be transported into the 1# horizontal rotary heating furnace by using oil pump, At the same time open heating system equipment (oil burners, natural gas burners etc..) start heating pyrolysis distillation, when heated gradually to reach 120 - 360 ℃ each fraction temperature, each fraction of gas into high efficiency atmospheric fractionating tower CT-101 for fractionation. Enter into the condenser --cooling tank -- go into oil-water separator - go into the middle oil tank (light diesel ,diesel) - through oil pump go into refining filter for filtering -- into end middle oil tank (light diesel, diesel).

High efficiency atmospheric fractionating tower CT-101 tower bottom oil return back into the transport at any time - through high temperature oil pump transport - reflux to 1# horizontal rotary heating furnace continue heating for pyrolysis distillation, according oil pyrolysis distillation situation, check the quality and yield of oil, spot check the tower bottom oil, fixed period transport the tower bottom residue oil to condenser through high temperature reside oil pump, go into cooling pool, then go into residue oil tank.

Waste gas recovery and utilization: non-condensable combustible gas into exhaust pipe, through two stages filtration waste gas treatment vacuum tank connected fractionator tower top reflux tank to combustible gas pipe network, together delivery to the combustible gas fire retardant storage cabinet, then enters the furnace combustion chamber burning instead of fuel. Not only energy saving and environmental protection.

Smoke and dust removal system, Once start run machine, light heating furnace, start-up draft fan, transport smoke to waste heat energy processors, then through the tower type spray remove smoke and dust two stages processor enter the draft fans, treat the smoke to white smoke up to standard emissions.

6. Why Choose Us

A. 10 Years Manufacturing Experience.

B. Exported machine to more than 50 countries.

C. Free Installation, Debugging and Training.

D. 2 Years Warranty for whole set machine and lifetime maintainance.

E. Alloy Steel material ensure the whole machine lifetime ≥10 Years.

F. The liftetime free wearing parts.

G. Eco-friendly machine and lifetime Tracking Service.

7. Certifications

8. Customer Visiting

9.Running Machine

Product Categories : Oil Refinery Machine > Used Oil Refinery Machine