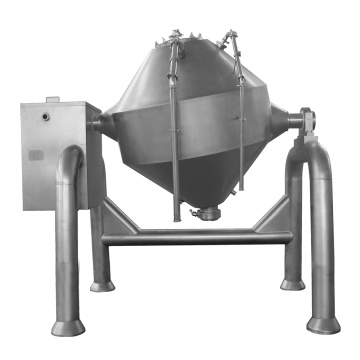

Powder/Vitamin Rotary Blending Machine

Product Description

Working Principle

The equipment is designed by three eccentric principles including centerof gravity eccentricity, axial eccentricity, upper and lower eccentricity, andsix direction asymmetry including up and down volume asymmetry, leftand right volume asymmetry, front and back volume asymmetry Sideddifferent capacities and multi-directional cross dislocation motion aregenerated on the basis of design principle for optimizing mixing ettect

Technical Parameter

| Specification(L) | ZPH-1m³ | ZPH-1.5m³ | ZPH-2m³ | ZPH-20m³ |

| Total Volume(m³) | 1 | 1.5 | 2 | 20 |

| Working Volume(m³) | 0.6 | 0.9 | 1.2 | 12 |

| Motor Power(kw) | 3 | 4 | 5.5 | 30 |

| Maximum Speed(rpm) | 6 | 6 | 6 | 6 |

| Diameter Of Feeding Port(mm) | 450 | 450 | 450 | 500 |

| Diameter Of dischange valve(mm) | 250 | 250 | 250 | 300 |

| Overall Dimension | 2365 | 2775 | 3128 | 5254 |

| 1572 | 1815 | 2012 | 3318 | |

| 500 | 500 | 600 | 600 | |

| 2630 | 3012 | 3146 | 5949 |

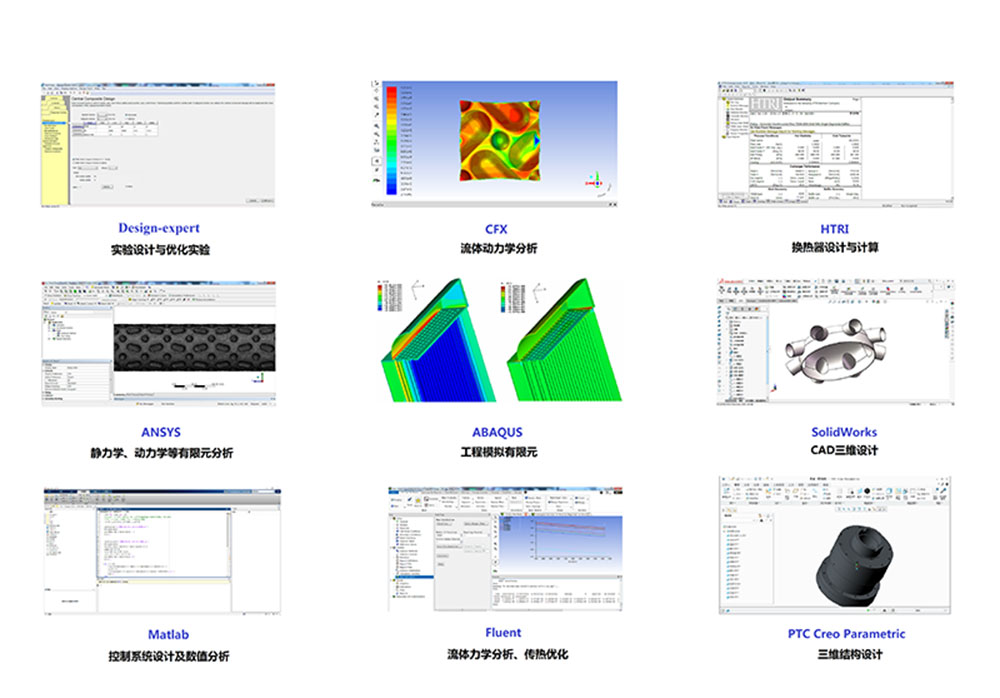

Design / Calculation Software

1. Multifunctional “Three in One” (filtering, washing and drying)

3. Sterile double-cone dryer

4. Rake Vacuum Dryer /Paddle Vacuum Dryer

5. Plate-fin Heat Exchanger

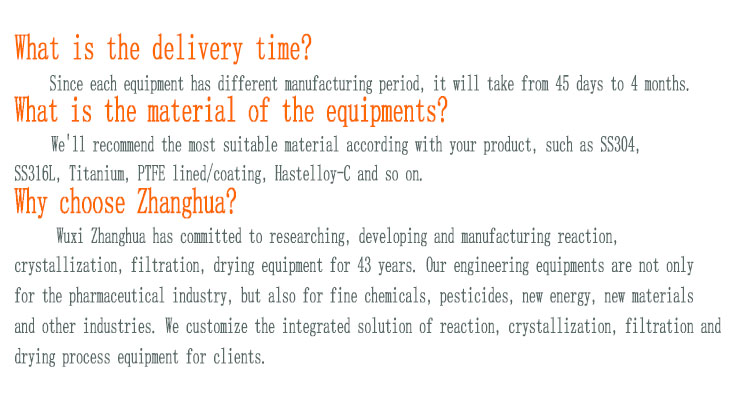

➤Our advantage

1. Special Equipment: Pressure Equipment, Equipment made of anti-corrosion materials, Sterile Equipment

Equipment made of anti-corrosion materials includes: anti-corrosion lining plastic/ PTFE/ enamel,

Ti/HC22/Mone11

2.Customized Design: Double-Cone in 20L-20m³

Rake Dryer (with mechanical seal) in 16 m³

DN300-DN600 “Three in One”

3.Design/Calculation Software

➤Scope of business

1. On-site Inspection

2.Technical Innovation Plan for Equipment Technical Improvement Plan for Equipment’s Structure Optimization Fast and Effective Solution to Equipment Malfunctions Highly Efficient and Precise On-site Construction Service Commitment to a Deadline in Customization A Full Range of long-term on-site technical maintenance service

4. Technical Solutions

5.On-site Testing and Training

6. Spare Parts

Product Categories : Mixing Machine > Vertical Tapered Mixer