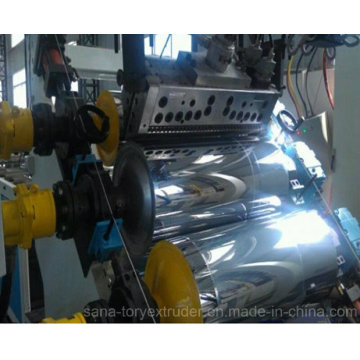

New Design PET Sheet Extrusion Line/Plastic Extruder

Basic Info

Model No.: ST-120

Product Description

Model NO.: ST-120 Plastic Processed: Pet Feeding Mode: Multiple Feed Screw: Single-Screw Screw Channel Structure: Deep Screw Automation: Automatic Food Packing Pet Sheet Machinery: Good Processing Capacity Single Screw Extruder: Very Low Noise Trademark: Sana-tory Origin: China Type: Sheet Extruder Product Type: Extrusion Molding Machine Assembly Structure: Integral Type Extruder Engagement System: Full Intermeshing Exhaust: Exhaust Computerized: Computerized High Speed Production: CE Approved advanced design: low energy consumption Specification: CE HS Code: 84772090 New Design PET Sheet Extrusion Line/Plastic Extruder

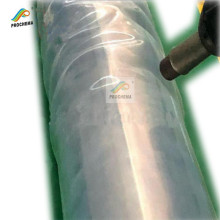

The PET sheet is widely applying for packing industrial such as food, electronic parts, medicine, stationary and tool etc.

Features:

1, This sheet line is especially for single and multi-layer sheet.

2, Thickness: 0.15mm to 1.5mm.

3, Width: 500mm to 1500mm.

4, Capacity: 200kg/h to 500kg/h.

5, PP, PS, PE are available on the same machine.

We are offering the whole line include crystallizer-dehumidifier, extruder, screen changer, gear pump, die, 3-roller calander, cooling rocket, haul-off unit, 2-station winding unit^etc. As a turn-key line.

Main Applications:

This line has large output and stable operation with high automation which can use 100% recycled PET material.

It has the features of good processing capacity, transparency, innocuity, no smell and no pollution.

Vacuum forming, food packing, toy box, stationery cases, tools and hardware packing.

Obstruct application, electron components packing.

Normal application, fold forming, under collar, decorate material, file folder, paper file, documents cover, credit cards.

Special application, medical equipment, medicine packing, industrial antisepsis, plate for microwave oven

Advantages and brief introduction of this line:

1. Rich experience, one of the earliest manufactures of plastic machinery in China, years of manufacturing experience and trial experience.

2. Pay attention to the use of materials, workmanship.

3. Software advanced, easy to operate.

4. Excellent engineers, technical support.

5. This line included the drying system, extruder, mould, three-roller calendaring, bracket of cooling roller, haul-off unit, winder etc.

Technical date:

Contact us if you need more details on Sheet Extrusion Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pet Sheet Extruder、Plastic Sheet Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

The PET sheet is widely applying for packing industrial such as food, electronic parts, medicine, stationary and tool etc.

Features:

1, This sheet line is especially for single and multi-layer sheet.

2, Thickness: 0.15mm to 1.5mm.

3, Width: 500mm to 1500mm.

4, Capacity: 200kg/h to 500kg/h.

5, PP, PS, PE are available on the same machine.

We are offering the whole line include crystallizer-dehumidifier, extruder, screen changer, gear pump, die, 3-roller calander, cooling rocket, haul-off unit, 2-station winding unit^etc. As a turn-key line.

Main Applications:

This line has large output and stable operation with high automation which can use 100% recycled PET material.

It has the features of good processing capacity, transparency, innocuity, no smell and no pollution.

Vacuum forming, food packing, toy box, stationery cases, tools and hardware packing.

Obstruct application, electron components packing.

Normal application, fold forming, under collar, decorate material, file folder, paper file, documents cover, credit cards.

Special application, medical equipment, medicine packing, industrial antisepsis, plate for microwave oven

Advantages and brief introduction of this line:

1. Rich experience, one of the earliest manufactures of plastic machinery in China, years of manufacturing experience and trial experience.

2. Pay attention to the use of materials, workmanship.

3. Software advanced, easy to operate.

4. Excellent engineers, technical support.

5. This line included the drying system, extruder, mould, three-roller calendaring, bracket of cooling roller, haul-off unit, winder etc.

Technical date:

| Line model | Extruder model | Main motor power | Sheet width | Sheet thickness | Line Speed | Maximum yield |

| PET-120 | SJ120,SJ65 | 132kw,45kw | 500-1200mm | 0.20-2mm | 5-25m/min | 550kg/h |

| PET-150 | SJ150,SJ90 | 185kw,75kw | 800-2200mm | 0.25-2mm | 5-20m/min | 750kg/h |

Product Categories : Plastic Sheet/ Board Machine

Premium Related Products

Other Products

Hot Products

EPE Foamed Net/Foamed Package Mesh MachinePE Heat Shrink Film MachineWood Plastic Profile Production Line (JG-MSX)Plastic Net Marking MachineWPC Three Layers Skinning Foam Plates Making Machine (JG-MSC)pvc hot-cutting pelletizing lineHot sale PET sheet production line PET sheet extruder plastic pet sheet making machine made in ChinaEuropean tech, chinese price high efficient parallel twin screw extruderPVC pipe machine with good price / PVC pipe production line/ PVC pipe making machineHigh quality HDPE steel reinforce pe pipe production lineplastic recycling machineryhorizontal mixing machine for plastic industryNew generation WPC extrusion line,WPC production line,WPC machineryFT single wall corrugated pipe extrusion line pvc pipe extruding linePlastic pipe belling/expanding machine for pipe production linehot sale high quality double pvc pipe making machine